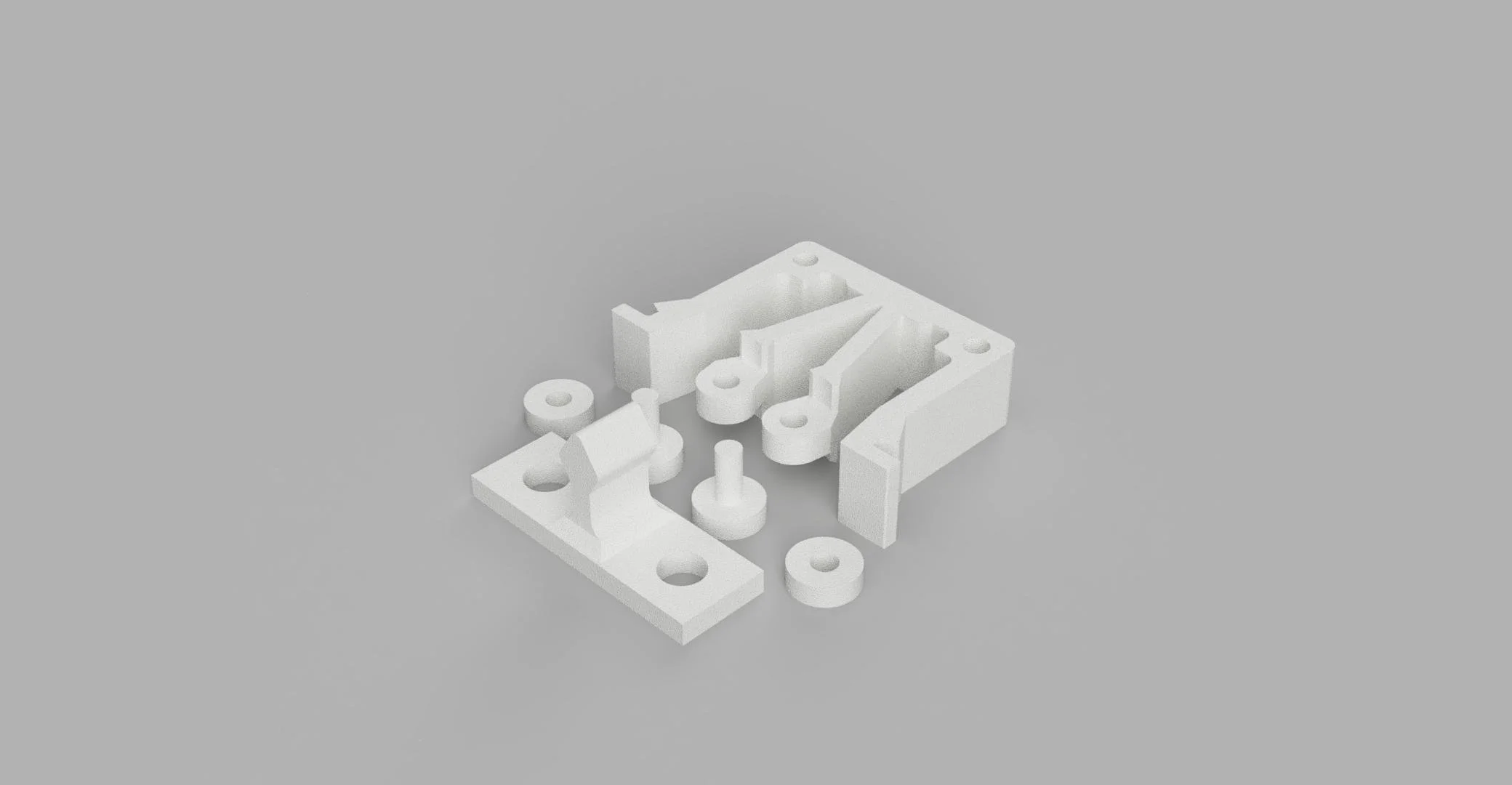

The Gyrus Series Mailbox started as an empty CAD file, growing over months to include over 20 components. Custom 3D-printed door latches, flag mechanism, and door stop, all Made in USA, ensuring top quality. Every component is tailored for the Gyrus, making it the highest-quality mailbox available.

Latch assembly

Flag Mechanism

The Gyrus Series Mailbox begins as a flat sheet of USA-made steel, precision-cut by a CNC plasma cutter for tight tolerances and repeatability. After removing dross, the sheet is prepared for bending, welding, and embossing. A slip roller forms the mailbox’s top radius, a bead roller embosses the floor, and a brake press completes the bends for multiple components.

Fresh steel delivery

Plasma cutting

Mailbox floor after embossing

After bending, all components are sandblasted and cleaned with acetone to prepare an optimal surface for powder coating. Each part receives two layers of powder coat—one color coat and one clear coat—for a durable, long-lasting finish.

Fluorescent Orange flag

Powder coated components

In the final assembly stage, the Gyrus Series Mailbox is riveted together using 53 USA-made 5052 aluminum rivets and sealed with marine-grade adhesive/sealant. A pressure-treated wood base is attached to the floor for easy installation. The mailbox flag and flag mechanism, secured with rivets, incorporate two USA-made thrust bearings for smooth, precise movement, designed to endure tens of thousands of cycles. Each mailbox is inspected and tested for binding or defects, ensuring premium quality.

Pressure treated wood installed

Small video during final assembly